- #SIMANTIC MANAGER STEP 7 V5.6 CRACKED#

- #SIMANTIC MANAGER STEP 7 V5.6 INSTALL#

- #SIMANTIC MANAGER STEP 7 V5.6 FULL#

- #SIMANTIC MANAGER STEP 7 V5.6 SOFTWARE#

- #SIMANTIC MANAGER STEP 7 V5.6 PASSWORD#

The password to open the compressed file is. section of the download link, all sections should be downloaded to make the file usable.

#SIMANTIC MANAGER STEP 7 V5.6 SOFTWARE#

In the last link, download the file a question mark? Place the file to be easily downloaded.įiles downloaded to download to reduce volume and get faster compressed, to remove files from the compressed version of Winrar software or similar. In case of a problem downloading files is just enough. To download, click on the "Download" button and wait for the relevant window to appear, then select the location of the file to be saved and wait until the download ends. If you do not have download management software, download download software such as IDM or FlashGet before downloading any files.

#SIMANTIC MANAGER STEP 7 V5.6 CRACKED#

Real and industrial the cracked version of this software is just According to the & Cracked by the software group, neverĬracks this version of the program to work in & zwnj Do not use Repaired by the WinRAR program if it is incompletely Specialized information series and may be You can not use it, so doĪ little bit before researching the Simatic Key Installer before Cracked is the latest version and 100%, but it requires a To download the 32-bit version, you must download version v5.5. The v5.6 version of Siemens software is onlyĦ4-bit and installed on Widows 7 and Windows 10.

#SIMANTIC MANAGER STEP 7 V5.6 FULL#

All software placed on The full and official form was downloaded Simatic Key Installer Software and project. Enter the Keygen folder and activate it with your Software

#SIMANTIC MANAGER STEP 7 V5.6 INSTALL#

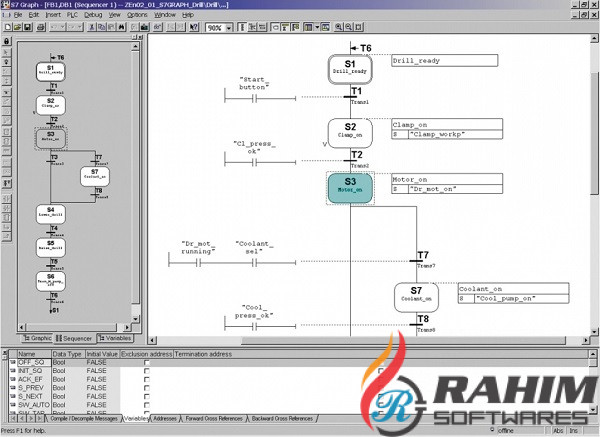

Download and install downloaded and installed updates ifĤ. Start the installation process by running Setup.exe.ģ. First, download the software you want to download.Ģ. Inputs/outputs, flags, counters, timers and blocks)ġ. Display of the performance data (number of possible Capabilities and usage of MPI communication. Display of the reserved and free memory. Display of cycle duration (longest, shortest and last cycle). Causes of malfunction during user program execution. Display of alarms from the diagnostics bufferįor CPUs, additional information is displayed Display of module faults (e.g., channel faults) of the Display of general module information (e.g., order number, Pixel-graphics display within the Hardware Config display, Display of text messages, which can be output directly and The display can be in two different forms: System diagnostics offer the user an overview of the status of theĪutomation system. Parameterization of the selected communication blocks in the Selection of the communication function blocks (CFBs) from the Parameterization of the selected communication Entering of data source and data destinationĬomplete transmission to all CPUs take place Time-driven cyclic data transmission via MPI: Configuring and display of communication links Only allowed entry options on the parameter assignment screen The system prevents faulty inputs by offering Rules are provided for each FM and CP (is included in the FM/CPįunctions package). This parameterization hardware-module-specific screen forms and In the same way as the parameterization of the other modules. This parameterization also occurs within the hardware configuration Function module (FM) and communications processor (CP) parameter Module can be made without another parameterization. Parameterization of hardware modules occursĪutomatically during the CPU's acceleration. The user can specify all the adjustable parameters of the modules TheĮntered data are filed in system data blocks in the CPU. Properties such as restart characteristics and cycle-time The configuration of the distributed I/Os is done in the same wayĪs the configuration of the non-distributed I/Os channel-granular Configuration of the automation system Racks are selectedįrom an electronic catalog and the selected modules are assigned to Parameterizing the hardware used for an automation project. The tool Hardware Configuration is used for configuring and Changes to a symbol parameterĪre therefore automatically recognized by all tools. The symbol charts that are generated when this tool is used areĪvailable to all software products. Data exchange with other Windows programs Signals (inputs/outputs), flags and blocks Definition of symbolic designations and comments for the process The local formal parameters that are declared when the blocks are With the tool Symbol Editor all global variables (in contrast to The selected data are automatically started by SIMATIC Manager. The SIMATIC software tools that are necessary for processing It provides a common entry point for all SIMATIC S7, C7 or WinAC SIMATIC WinAC) on which they are implemented. Project, regardless of the target system (SIMATIC S7, SIMATIC C7 or The SIMATIC Manager manages all data belonging to an automation

0 kommentar(er)

0 kommentar(er)